走进格林美

格林美江西循环产业园成立于2010年5月,是格林美集团在丰城投资建设的第二大循环产业基地,总占地1500余亩,建设了电子废弃物循环产业园、废五金循环产业园与废钢铁循环产业园以及江西城市矿产资源大市场等四大园区。

查看详细

Significant Technological Progress

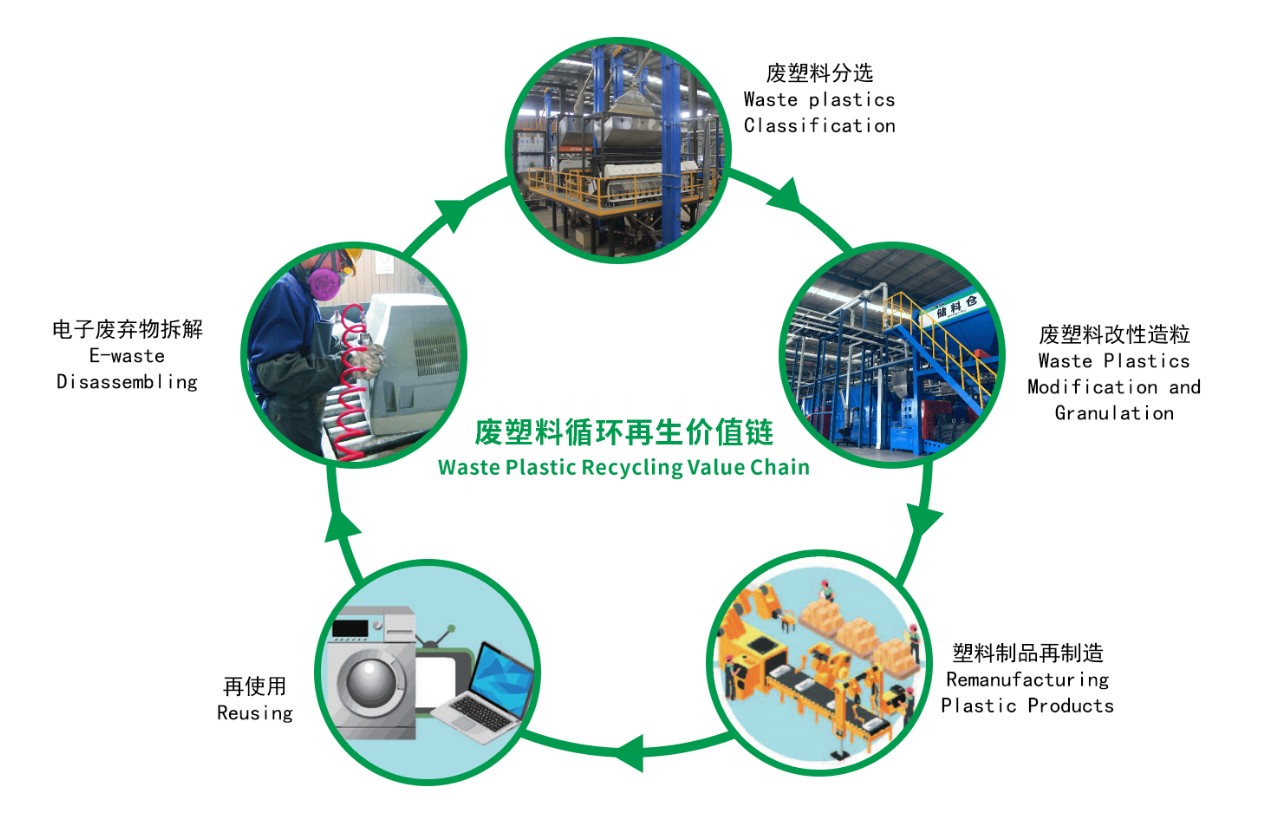

Up to date, GER has established a closed-circuit cycle economy model of waste plastic products, namely, “waste products - recycling and disassembly - resource development - modification and regeneration - new products”. The company is working hard to industrialize the research results, thus improving the recycling and reuse of wastes, gaining a wonderful technical development and engineering foundation in the recycling of e-waste, high-value utilization of scrapped circuit boards and efficient recycling of waste plastics. It has built many demonstration lines.

(I) Disassembly of E-waste

Targeting at typical e-wastes such as waste TV sets, microcomputers, washing machines, refrigerators, air conditioners, LCD displays and waste circuit boards, GER has developed technical equipment and solved engineering problems such as cleaning and treatment of waste circuit boards, recycling and high-value use of metal materials, efficient collection and centralized disposal of e-wastes, intelligent identification and fine sorting, etc. As a result, GER has established the technical system of integrated innovation, realized the full-component recycling, full-element utilization and fine re-manufacturing of e-waste, and provided the engineering demo for the “urban mineral” resource recycling industry in China.

(1)GER has developed the low-temperature continuous pyrolysis technology, thus realizing the cleaning and treatment of waste circuit boards

To solve such problems as the mixture of metal and organic components in waste circuit boards, low recycling efficiency of conventional metal treatment and difficult elimination of persistent organic pollutants, GER has developed the innovative technology of low-temperature continuous pyrolysis for waste circuit boards. At the same time, it has designed on its own the large-scale industrial apparatus, thus realizing the continuous cleaning and treatment of waste circuit boards and effective metal enrichment.

(2) GER has invented the new technology of cascade separation and recycling of valuable metals in e-waste, thus realizing the recycling and reuse of copper, aluminum, iron, gold, silver, platinum and palladium.

Considering the different types of metal materials produced in each stage of the e-waste treatment that have different purity, GER has developed the new technology of short-process re-engineering metal alloy products and cascade separation and recycling, which has realized the graded use of valuable metals in e-wastes. The recycling rates of copper, aluminum and iron have exceeded 98.7%, and those of gold, silver, platinum and palladium stand above 99.6%.

To solve such problems as low automation, poor processing environment and low recycling rate of plastics in the disassembly of used home appliances, GER has proposed a model of multi-layer material transportation, and developed an automatic dimensional disassembly system and the technologies of controlled crushing of e-waste, fine sorting and high-value use of plastics.

To solve such problems as extensive distribution, ambiguous formation rules, imperfect recycling network and low efficiency in the recycling process, GER has built a typical city mineral data system, clarified the law of e-waste generation and distribution, created the Internet+ category recycling mode, and developed the IoT whole-process traceability information platform.

To solve the technical problems of identification and separation in the recycling and disassembly of used home-appliance plastic in China, GER has industrialized its new e-waste plastics sorting technology, thus manufacturing a set of reasonable, effective and economical equipment and technology for the sorting of used home-appliance plastics. It has realized the industrialized demo line of clean and efficient sorting of waste home-appliance plastics. In this way, the production capacity of recycled and modified plastics has reached 60,000 tons, and the products have entered the supply chain of the Fortune World Top 500 companies, thus becoming China’s leading manufacturer of recycled and modified plastics.

Address:Resources Recycling Industrial Base, Fengcheng City, Jiangxi Province.

Phone:0795-6833888

Fax:0795-6833666

Scan QR Code

SiteMap · AuxiliarySection · BottomGraphic · About GER

Jiangxi ICP No. 2020014411-1© 2008-2020 Jiangxi Green Recycling Co., Ltd. All rights reserved